Rice is a rich source of macro and micronutrients. During rice milling,

the fat and micronutrient-rich bran layers are removed to produce the

commonly consumed starch-rich white rice. White rice is the number one

staple food in the rice countries of the southeast and northeast Asia,

one of the most densely populated regions in the world. Of the world’s

rice production, 90% is grown and consumed in Asia. On average, 30% of

calories come from rice and this can increase to more than 70% in some

low-income countries. In most languages of these regions, the words for

rice and food are synonymous. It should be noted that rice is also an

important staple food in several African countries and the

Americas.

In recent years, rice fortification

technology has evolved. As a result, rice fortification at scale is

gaining momentum as a feasible and cost-effective strategy to address

micronutrient deficiencies. To date, about 15 countries have introduced

rice fortification on either a mandatory or a voluntary basis, embedded

in social safety nets, or at a limited scale through

trials.

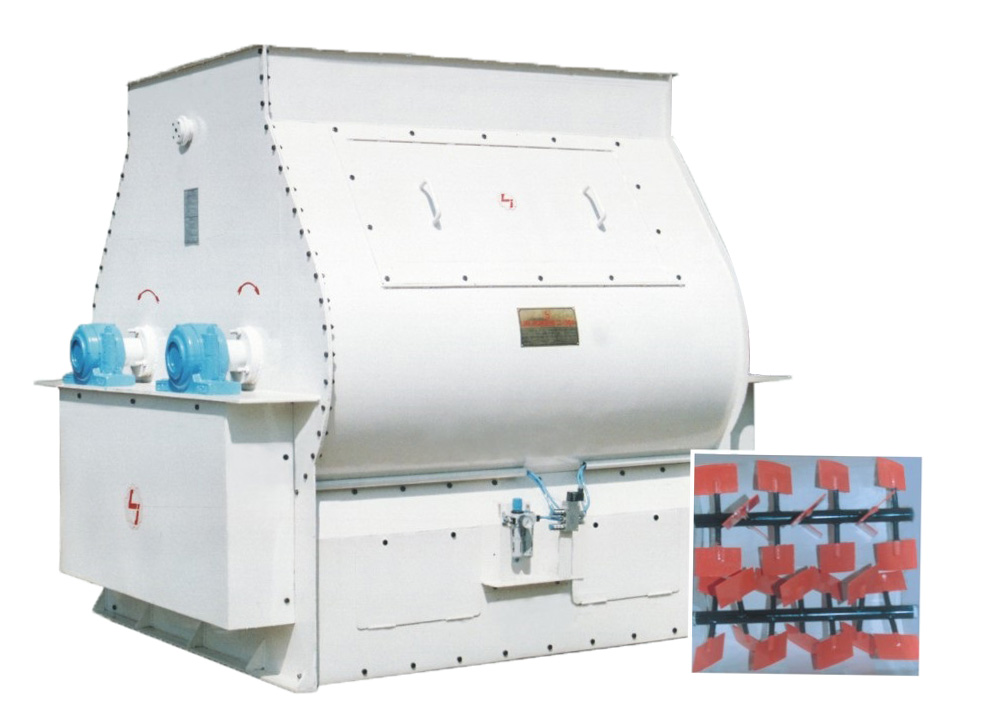

Fortification of rice needs precision mixing;

for this, we have specially designed “DOUBLE SHAFT PADDLE

MIXER”. This is a new generation mixing technology patented by

the Norwegian inventor Halvor Forberg and is also popularly known as

the Forberg fluidized zone mixer with demanding precision Mixing and to

provide homogeneous mixtures of physically adverse particles

incorporated at various level in the mix.

This

machine is based on a weightless zone or fluidized zone mixing

technology with many modifications at Lark Engineering. In this machine,

two shafts are positioned in a double drum housing on which series of

blades are fixed. The two shafts rotate at a specific peripheral speed

in the opposite direction while paddles on each shaft overlap in the

middle of the mixing drum. This lift all the ingredients in the middle

and creates a fluidized zone by neutralizing gravitational forces

working on particles of different ingredients having different shapes,

sizes & density. Hence, a very homogeneous product is received.

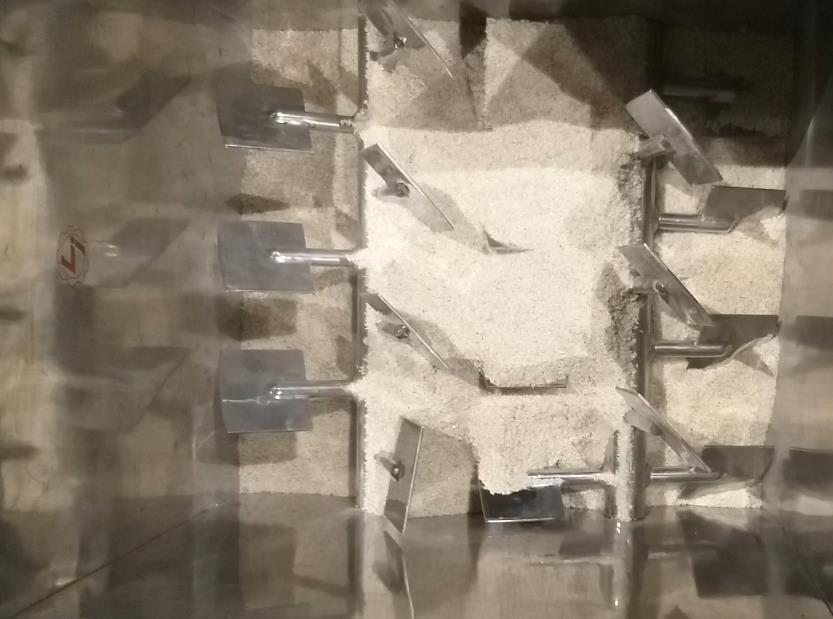

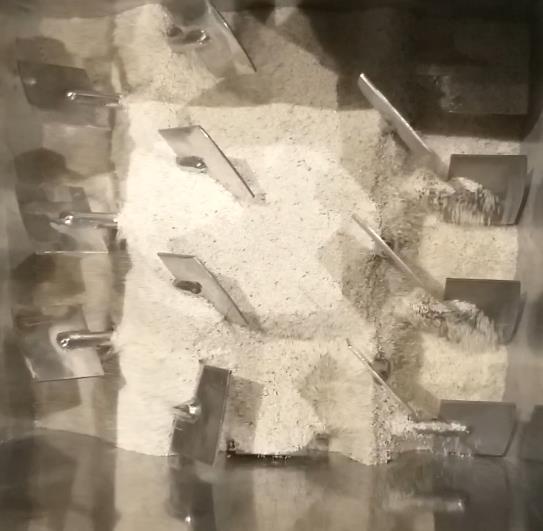

The next step is to discharge the highly homogenized material from the

mixer without segregation. For this, the material is discharged very

quickly with the help of two pneumatically operated large bottom

discharge doors. The filling level is another feature of this mixer, as

it can work equally well with 40% overfilling and 60% underfilling of

its nominal filling level. The nominal filling level is the level up to

the shaft of the mixer.

For liquid addition, the

material should be filled at least 120% level when pin-mill or FDB is

used.

Homogeneous mixing between RICE and FRK can be

achieved up to 1:100, 1:200 and even up to 1:2000 with negligible rice

breakage and dust formation. In collaboration with the Government of

Bhutan and the World Food Programme committee, we recently designed a

complete project for Rice Fortification of 5 MT/HR. The project is fully

automatic with PLC Controlled auto batching and

auto-bagging.

We have a wide range of projects as per

the customer need starting from 1 TPH to 25 TPH for Rice

Fortification.

Here are some details of the in house

successful trial of Mixing of Standard Rice with Fortified Rice in the

presence of Bhutan Government officials & world food program

committee representative;

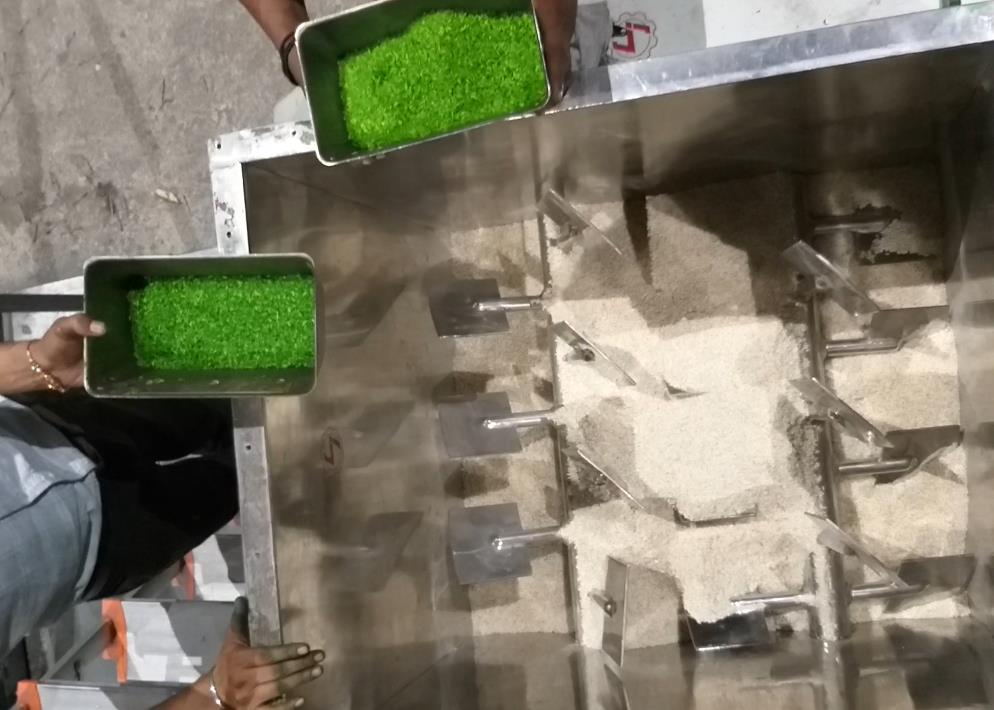

Double shaft

Paddle Mixer

Food

Grade Color in 1 kg of rice

Colored

Rice – Approx. 1 KG

100 kg

rice in Double Shaft Paddle Mixer

1

kg. Colored Rice – Addition

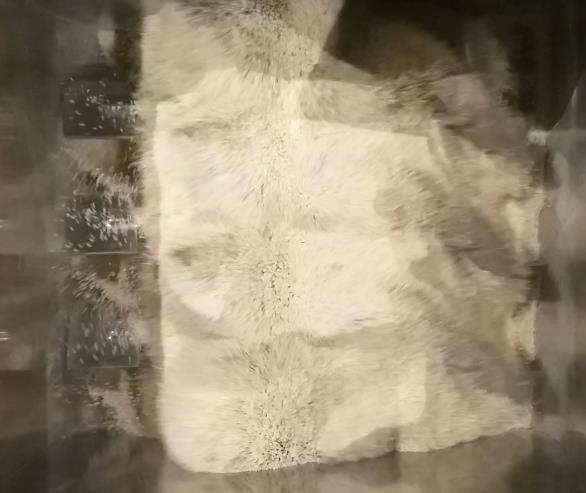

After 2

seconds

After 3

seconds

After 5

seconds

After 7

seconds

Homogeneous

Dispersion within 7 seconds

The above information is based on data collected

from our existing customers & internet sources and is only for

your reference. As expertise in feed mill engineering only, Lark

Engineering will not be responsible for any type of loss occur due to

the above stated information.