Mash Feed

Animal feed consists of different ingredients to make a balanced diet in terms of proteins, carbohydrates, fats, vitamins, minerals and medicines etc. In manufacturing of feed in mash form, there are few ingredients like DRB, Rice Polish etc which are already available in powder form, while some of these like Grains, Fish, GNE, Soya etc. are available in solid form and has to be converted to granular form to particle size suitable for the animal. For this purpose grinding of these ingredients is carried out with the help of Grinder or Hammer Mill.

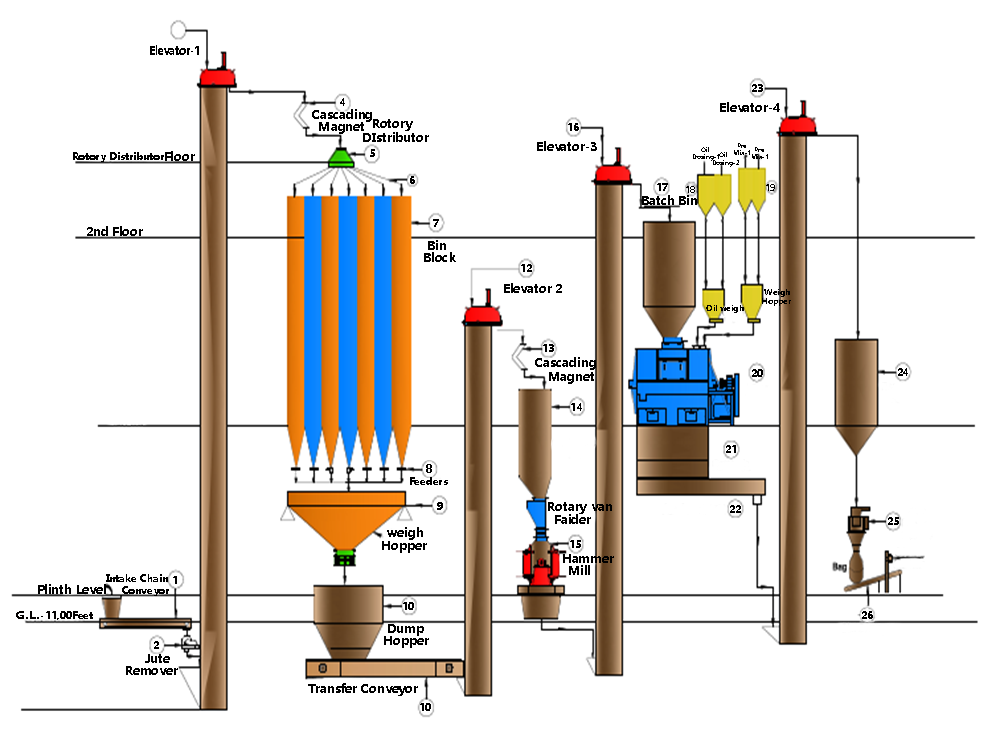

After converting all the ingredients in the powder form, these have to mix in right proportions to get the homogenous feed. Mixers are employed for this purpose. So there are two basic operations of grinding and mixing in feed manufacturing of feed in mash form. The intake hopper of the grinder and top of mixer are usually at some height between 5 to 8 ft (Depending upon the size of machine) from floor level and material have to be lifted at this level manually. For auto lifting of feed from floor level to the top of machine Screw Conveyors are employed.

The Features that are generally desired in mash feed plant as follows:- It should give consistent output for which it is designed.

- In Grinding it should give desired texture with uniform grinding.

- In mixing it should give accurate mixing in shortest time.

- It should have provision of reliable magnetic separator.

- Ease of control in feeding of raw materials.

- All the machines should be of matching capacity.

- It should have minimum dust with good working conditions.

- It should consume minimum energy per ton of feed processed.

- Highly reliable with minimum breakdown.

Working on these desired features, our innovative team of engineers with years of experience in equipment design has come up with new solutions to meet your specific needs.After analyzing your individual requirement of in terms of throughput and quality of final product, we will make a suitable combination of machines. In grinding, now we have three designs to offer you i.e. Half Screen, Full Screen, Our patented QGA series, and three designs in Horizontal Mixer - Paddle Mixer, Double Ribbon Screw Mixer and Double Shaft Paddle Mixer.

In magnetic separation we have developed cascading magnets of self cleaning design with high cleaning efficiency. LARK can offer Mash Feed Plants of any capacity (say 2 ton/hr – 100 ton/hr or more) with optional auto bagging or auto batching (pre-weighing), single line to multiple lines of grinding and mixing. Here we are giving brief details of our Standard Mash Feed Plants upto 16 ton/hr.

Different variants

1 - 1.5 TPH Mash Feed Plant

3-4 & 4-6 TPH Mash Feed Plant

14-16 TPH Mash Feed Plant

16-20 TPH Mash Feed Plant

Get Quote Now

We are here for you. Please feel free to ask anything?