Double Shaft Mixer

Double shaft paddle mixer, also called Horizontal Non-gravity Mixer, it is an advanced mixer machine with high efficiency, high uniformity, high intensity and low energy consumption. The machine is widely used for mixing powder-powder and powder-granule, especially suitable for materials with big difference in specific gravity or particle size.

This machine is based on weight less zone or fluidized zone mixing technology with many modification at lark Engineering. In this machine, two shafts are positioned in a double drum housing on which series of blades (generally 14 on each shaft) are fixed. The two shaft rotate at a specific peripheral speed in opposite direction while paddles on each shaft overlap in the middle of mixing drum.

Technology Working principal

This lift all the ingredients in the middle and creates fluidized zone by neutralizing gravitational forces working on particles of different ingredients having different shapes, sizes & density.

Filling Level

Filling level is another feature of this mixer, as it can work equally well with 40% overfilling and 60% under filling of its nominal filling level. Nominal filling level is the level upto the shaft of the mixer.

Liquid Addition

The provision of single shaft with rotating pins positioned at the fluidized zone of the mixer is called Flow Distortion bar. The Flow Distortion Bar creates curtains of particles to which the liquid can be sprayed by providing a spray bar with nozzle arrangement.

Pin mill system

The pin mill system provision in fluidized zone of mixer consists of two counter rotating shaft with pins. When both the shafts are counter rotating through the fixed pins welded on the shroud on the top, they create the required shear force to break the soft lumps.

Our double shaft paddle mixer has following strong

points :- - Mixing Quality: Homogeneous mixing of different ingredients irrespective of density,shape and size of ingredients in short time(CV less than 5 percent is easily achieved with in 30sec.to 180 sec)

- Product Heating: Due to large particle movement in fluidized zone and a relatively low speed counter rotating shafts very low friction and shear forces are generated ,hence heating as well as mechanical abrasion on products is greatly avoided which make it suitable for even for fragile products.

- Economy of Mixing : Power consumption per ton of the product mixed is very low.Similarly with negligible wear and tear,maintenance and running cost is also very low.

- Cleaning: Due to large access doors,cleaning is easy.

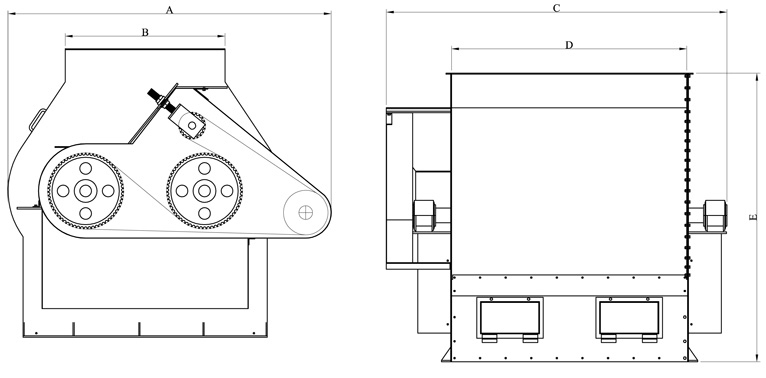

| Model | Batch Capacity | Power in H.P | Dimensions |

| Ltr | Cu.ft | A | B | C | D | E |

| DSPM -60 | 60 | 2.1 | 3 | 900 | 690 | 980 | 580 | 650 |

| DSPM -120 | 120 | 3.5 | 5 | 1110 | 850 | 1210 | 730 | 950 |

| DSPM -150 | 150 | 5.3 | 5 | 1220 | 960 | 1260 | 790 | 980 |

| DSPM -200 | 200 | 7.1 | 5 | 1350 | 1050 | 1350 | 80 | 980 |

| DSPM -350 | 350 | 12.4 | 7.5 | 1650 | 1240 | 1500 | 995 | 1150 |

| DSPM -500 | 500 | 17.7 | 10 | 1750 | 1370 | 1640 | 1150 | 1180 |

| DSPM -750 | 750 | 26.5 | 15 | 1950 | 850 | 1860 | 1300 | 1500 |

| DSPM -1000 | 1000 | 35.3 | 20 | 2200 | 900 | 2060 | 1450 | 1560 |

| DSPM -1600 | 1600 | 56.0 | 30 | 2550 | 1030 | 2400 | 1650 | 1750 |

| DSPM -2000 | 2000 | 70.0 | 40 | 2850 | 1150 | 2600 | 1890 | 2100 |

Get Quote Now

We are here for you. Please feel free to ask anything?