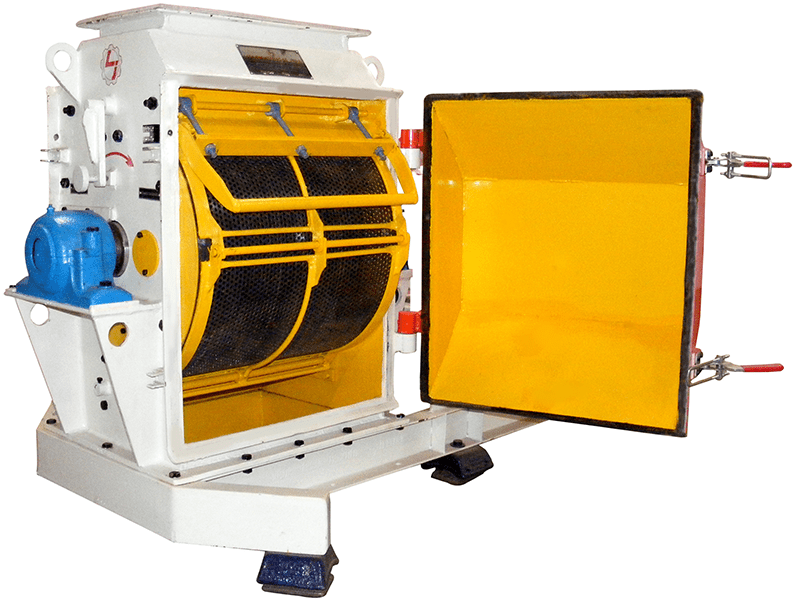

Full Screen Hammer Mill

As its name implies, Full screen hammer mill have 80 % screening area as compared to 50 % in half screen hammer mill. This machine is solution to many fine or coarse grinding problems that we usually face. In grinding chamber gap between tip and screen is very important for efficiency as well as quality of grinding, our hammer mill having the gap adjustment facility to be fit for fine or coarse grinding. Also our hammer mill has so many other features that make it an ultimate choice :

Technical specifications:

| Model FSHM | Capacity Kgs/Hr. Maize Grinding | Capacity Kgs/Hr.Mixed feed Grinding | Capacity Kgs/Hr. | Power (H.P.) |

| Starter 4mm | Grower 5mm | Finisher 6mm | Starter 4mm | Grower 5mm | Finisher 6mm | Millet grinding | |

| 1015 | 1800 | 3200 | 4000 | 2500 | 4000 | 5500 | 1800 | 10 -15 |

| 1525 | 2500 | 3800 | 4800 | 3200 | 4500 | 6800 | 2600 | 15 - 25 |

| 2040 | 4500 | 6500 | 9000 | 6500 | 8500 | 11000 | 4500 | 20 -40 |

| 3075 | 6000 | 8500 | 13000 | 8000 | 10000 | 13000 | 8000 | 30 - 75 |

| 50120 | 8500 | 10500 | 12000 | 1200 | 14000 | 16000 | 10000 | 50 - 120 |

Our patented QGA - technology

Inventing this technology is one more feather to our cap and a total grinding solution for all types of grinding. "Quick-Gap-Adjustment" QGA, as its name implies this technology is a boon for grinding different sizes of products as fine/ Medium/ coarse by quick change of gap between hammer tip and screen, thus creating ideal parameters for optimum grinding of product.

Grinding different sizes of product (fine/ medium/ coarse):In poultry feed, we need different particle size of feed referred to as fine or coarse to feed a day old chicks to full age broiler/ chicken. For optimum grinding we need different parameters for fine grinding or coarse grinding. In simple hammer mills, the required particle size is obtained by changing the hole size of screens while the other parameter of hammer mill such as tip speed of hammer mill, gap between hammer tip to screen, remain same.

In modern hammer mills, to obtain coarse/fine grinding following step are taken: - Screen of smaller hole for fine and bigger hole for coarse feed is used.

- Speed of motor can be changed by fitting a VFD (Variable frequency drive) or dual speed motor or D.C. motor.

- Gap adjustment between hammer tip to screen is varied by changing the position of hammers on different PCD on circular plates of rotor.

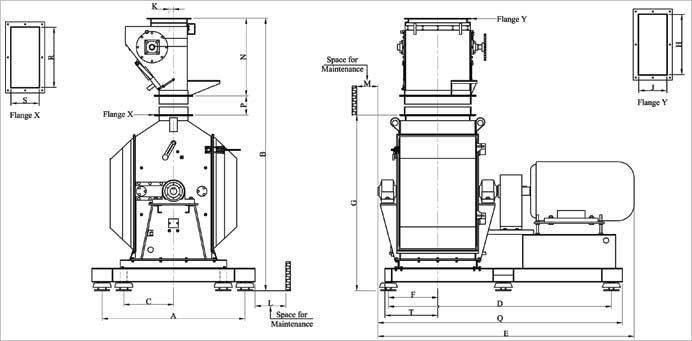

| Model FSHM QGA | Dimensions in mm | Approx. Weight in kg. | Vol. Seaworthy packing Cu.m. |

| A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R |

| 1015 | 642 | | 197.5 | 827.5 | - | - | 235 | - | - | - | 1000 | 750 | - | - | 1110 | 222 | 160 | 172.5 | 230 | 1.5 |

| 1525 | 777 | - | 215 | 1005 | - | - | 962 | - | - | - | 1000 | 750 | - | - | 1347 | 268 | 214 | 191 | 415 | 2.3 |

| 2040 | 777 | 1841 | 215 | 1295 | - | - | 962 | 430 | 220 | - | 120 | 915 | 704 | 175 | 1630 | 420 | 215 | 307 | 520 | 4.5 |

| 3075 | 785 | 1990 | - | 2005 | 280 | 412.5 | 1247 | 525 | 315 | 41 | 1200 | 915 | 704 | 175 | 2178 | 575 | 250 | - | 1000 | 6.4 |

| 50120 | 1280 | 2470 | 452 | 2025 | 2325 | 450 | 1592 | 525 | 315 | 41 | 1300 | 915 | 704 | 175 | 2218 | 575 | 250 | - | 1219 | 11.5 |

Get Quote Now

We are here for you. Please feel free to ask anything?